CMD-COAT™: A New Platform For Nanogel Innovation

Hydrophilic. Loadable. Durable. Scalable. Our patented nanogel platform is transforming medical device coatings — enabling multi-API delivery, superior passive protection, and a new approach to antimicrobial resistance.

CMD-COAT™ enhances device performance with exceptional coverage — all without disrupting existing manufacturing processes. Discover the innovations behind our solutions.

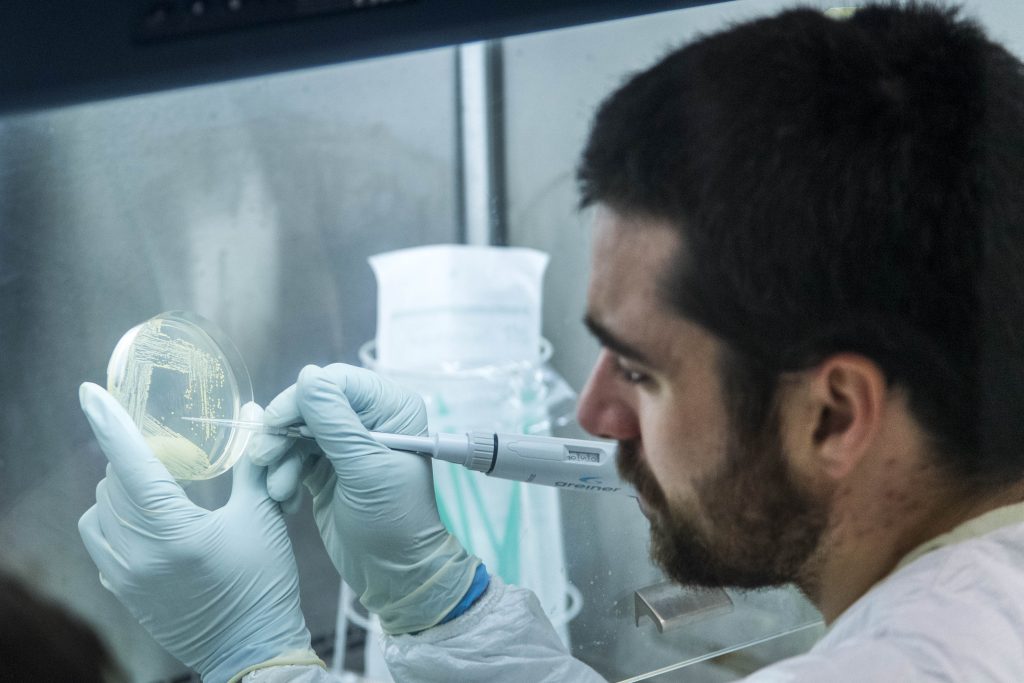

Behind the Breakthroughs

Advanced Coating Technology

Water-based Process

Our entire coating system — from formulation to process and application — is water-based. This creates a highly stable, biocompatible foundation with no need for aggressive solvents.

-

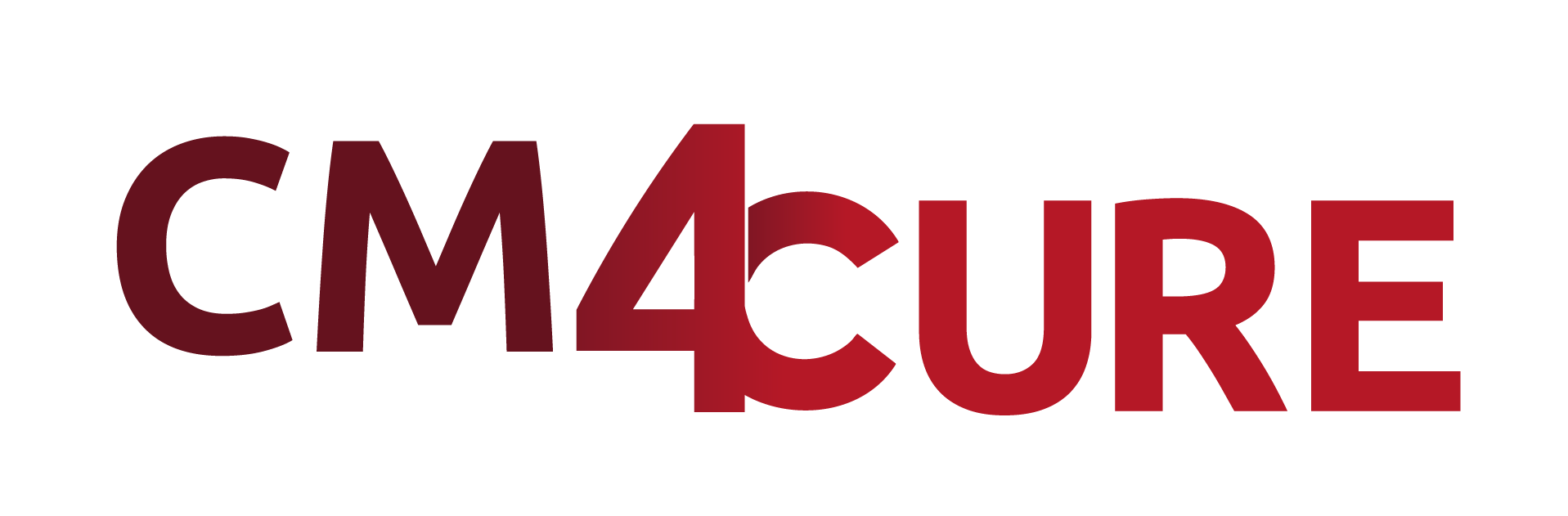

Multilayer, cross-linked nanogel coating

-

Nanogel structure remains intact — never released into the body

-

Strong covalent bonds

Platform for API Delivery

Our advanced platform can be loaded with up to six APIs — both water-soluble or insoluble. The patented polymer system enables targeted, progressive release up to 30 days.

- Supports 1–6 APIs in a single coating

- Enables both soluble and insoluble compounds

- Controlled release up to 30 days

- Patented nanogel platform enhances device performance

Flexible. Durable. Compatible.

CMD-COAT™ forms an ultra-thin layer with exceptional bonding strength. It works on extremely narrow diameters and adapts to even the most sensitive or complex devices without affecting flexibility or function.

- Nanometer-thin layer

- Strong adhesion

- No surface damage or material degradation

- Compatible with plastics, metals, and biological tissue

Passive Coating, Superior Protection

Even without APIs, CMD-COAT™ provides best-in-class device protection. The hydrophilic coating resists fouling from blood, proteins, and microbes — constantly protecting device surfaces.

- Superior antifouling performance

- Limits surface buildup and contamination

- Functions as a standalone protective barrier

Innovative APIs

Novel Mode of Action

A century after penicillin, we’re entering a new era of antibiotics. Our patented pyrimidine-based APIs reinvent how we target the bacterial cell wall — hitting multiple points to shut down even the toughest drug-resistant infections. This pleiotropic mechanism disrupts antimicrobial resistance, stopping infections at the source. CM4CURE

- Multiple cell wall targets

- Pleiotropic effects break resistance mechanisms

- Effective in preventing and treating difficult infections caused by both Gram-positive and Gram-negative bacteria

Engineered to Outpace Resistance

Antibiotic resistance is rising — turning manageable infections into serious threats. Our APIs work with antibiotics to enhance their effect, lower required doses, and have shown strong results in major clinical trials — with no known resistance.

- Boosts antibiotic effectiveness

- Enables lower antibiotic dosages

- Clinically proven results

- No known resistance

Fluometacyl®: Dual-action API

Our patented API is built from a metabolite of an FDA-approved drug with full toxicology data. It delivers strong efficacy without added regulatory burden. When Fluometacyl® is paired with CMD-COAT™, it produces the first dual-action coating with both antimicrobial and antithrombotic properties.

- First-of-its-kind antimicrobial and antithrombotic coating

- Proven synergy from known, safe components

- No added regulatory or chemical complexity

Future Applications

Medical device coatings are just the beginning. Our APIs are built for two key paths:

- Coating applications using FDA-derived API combinations — safe, effective, and ready for clinical use.

- Pharmaceutical development of novel antimicrobial APIs — targeting resistant infections through topical, oral, nebulized, and IV delivery.

Manufacturing-Ready. Scalable by Design.

CMD-COAT™ was engineered not just for performance, but for seamless integration into medical device manufacturing

— with no added time, complexity, or environmental burden.

Water-Based, Solvent-Free Process

Water-based mixing and application

Room temperature processing

No UV curing, thermal treatment, or post-processing required

More ecofriendly than solvent-based systems

Fast, Simple, and Familiar

No change to production timelines

Pre-mixed materials — no on-site chemistry required

Easy adoption with existing workflows

Wide Material Compatibility

Ultra-thin yet durable layer

No material deterioration

Maintains flexibility and function

Full Coverage - Inside and Out

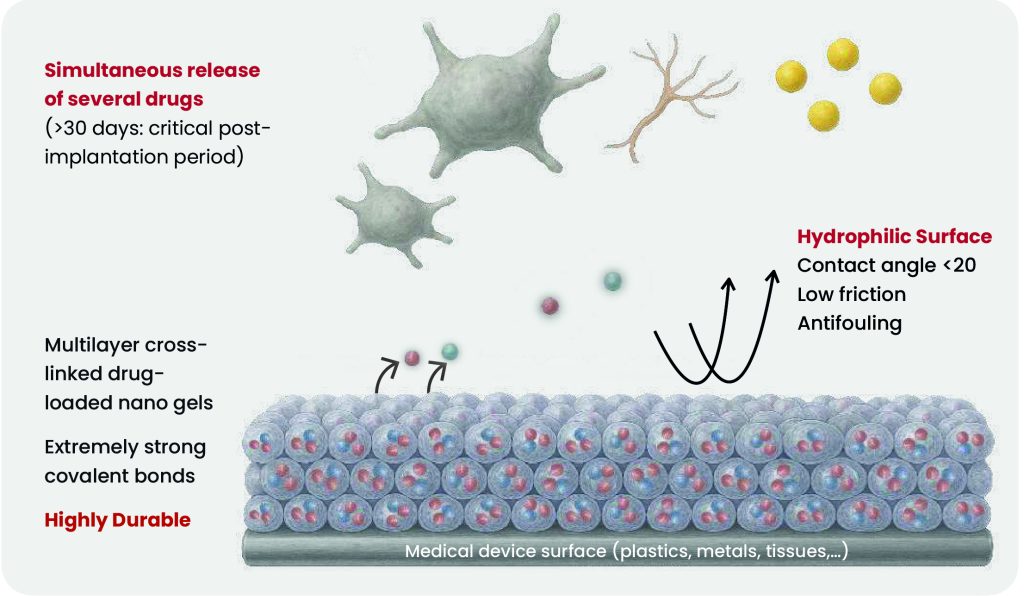

Solving Critical Risks in IV Catheters

Bloodstream infections from IV catheters can cost up to $46,000 per episode and carry a 15% mortality rate. Thrombosis affects up to 18% of patients, compounding risk and driving up costs. Existing coatings offer limited protection. CMD-COAT™ goes further.

Paired with our patented Fluometacyl® API, it delivers first-of-its-kind dual protection against both infection and thrombosis — all in a single, ultra-thin, hydrophilic layer.

CMD-COAT™ is designed to scale across insertable and implantable devices — and beyond. CM4CURE

0.1% - 9%

$46k per episode

15% Mortality

Bloodstream Infection

5% - 18%

$5k per episode

Increased Infection Risk

Thrombosis

Expanding What’s Possible

IV catheters are just the beginning. Our nanogel platform, CMD-COAT™, is designed to enhance safety and performance across a wide range of medical devices — from high-risk insertables to long-term implants.

Potential applications span:

- Urinary Catheters

- Port-a-Cath IV Access

- Heart Valve Implants

- Prosthesis

- Hemodialysis Catheters

- Breast Implants

- Stents

- Pacemakers

With programmable API delivery, exceptional passive protection, and potential for new API formats, it’s a new frontier for coating technology.

Meet the Team

Behind this revolutionary platform is a team of leading clinicians, scientists, engineers, and business strategists working to change the future of medical device coatings and patient care.